Location

İçmeler Mah. Çağdaş Sk. C No: 2 C

İç Kapı No: 268 Tuzla/İstanbul

İçmeler Mah. Çağdaş Sk. C No: 2 C

İç Kapı No: 268 Tuzla/İstanbul

RTS Marine offers immersion varnish services designed to protect and extend the lifetime of electric motors and alternators on ships. The harsh marine environment, with its high levels of humidity, saltwater exposure, and temperature fluctuations, can cause significant wear and tear on electrical components. By applying immersion varnish, we provide an extra layer of protection that helps these components withstand the challenging conditions at sea.

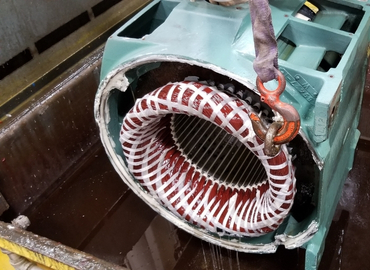

Immersion varnishing is a process in which electrical components, such as motor windings and alternator coils, are fully submerged in a protective varnish. This varnish forms a uniform coating over the entire surface of the component, sealing it from moisture, salt, and other corrosive elements that can cause damage over time. The result is improved insulation, enhanced durability, and increased resistance to environmental stressors.

The immersion varnish process begins with a thorough cleaning of the components to remove any dirt, oil, or moisture. This step is crucial for ensuring that the varnish adheres properly and forms a complete seal around the component. Once the component is cleaned, it is submerged in a specially formulated varnish designed to withstand the rigors of marine environments. The varnish is applied evenly, penetrating into all the nooks and crannies of the component to provide comprehensive protection.

After the varnishing process is complete, the component is baked at a controlled temperature to cure the varnish. This curing process hardens the varnish, making it resistant to cracking, chipping, and peeling, even under extreme conditions. The result is a durable, long-lasting protective layer that shields the electrical component from environmental damage.

One of the primary benefits of immersion varnishing is the improvement it provides in insulation resistance. By sealing the windings and other components, the varnish prevents moisture from penetrating the electrical system, reducing the risk of short circuits and other electrical failures. This is especially important in marine environments, where exposure to saltwater and humidity can quickly degrade insulation materials if not properly protected.

In addition to enhancing insulation, immersion varnishing also helps to improve the mechanical strength of the components. The varnish acts as a bonding agent, holding the windings and other parts together more securely. This reduces the risk of mechanical failure due to vibration or other stresses that are common in shipboard environments.

RTS Marine’s immersion varnish services are ideal for shipowners looking to extend the life of their electric motors and alternators. By protecting these critical components from environmental damage, you can reduce the frequency of repairs, minimize operational downtime, and ensure that your ship’s electrical systems continue to perform reliably over the long term. Our team of experts is highly trained in the application of immersion varnish, and we use only the highest quality materials to ensure optimal results. Trust RTS Marine to provide the protection your ship’s electrical components need to withstand the harsh marine environment.